Automation Services in Saudi Arabia

we provide automation services to many industries with excellent and long lasting results

Precise Automation for Reliable Results

When you need to automate a process, there are many different options. Precision Scientific Equipment can help you with your automation needs. We have a wide variety of automation services to choose from, so we can accommodate your needs and preferences. Our services include everything from simple tasks like monitoring equipment and sensors to more complex projects that require deeper analysis and customization. We use automation to make the process more efficient and to help ensure that the process is reliable.

We understand the importance of quality control, which is why we always make sure that our automation services are up to par. We also take pride in our customer service skills, which means that you always have someone available should you need assistance with your project or have questions about it. We believe that our capabilities and customer service make us the ideal choice for anyone looking for reliable, high-quality automation services. Our team has extensive experience in automation, and we are well-trained to help you with your automation needs, whether it’s SCADA or instrumentation and electrical installation.

Automation Process

It is vital to understand what an automated process is and why you should use Precision Scientific Equipment for your process when dealing with it. The automation process is a system or combination of systems that help to enhance the flow of information and materials, resulting in higher production and lower costs. To automate a process, you must first understand the process, the tools, and the technology you will be employing, as well as your goals. The automation process can provide several advantages. For example, it improves inventory tracking, productivity, and accuracy. It also helps to enhance the flow of information and material, which improves profitability and delivery performance.

Process automation

It is a long-term capital investment. Get it wrong, and downtime will cost you even more. It is crucial to work with a partner who understands the shop floor and automation, who has years of deep knowledge and experience and the certifications to prove it.

How We Do It

1. SCADA integrated to Siemens, Schneider, ABB, LS, Mitsubishi, Allen-Bradley PLC.

2. Configure number of clients as per customer requirements.

3. Integrated to any brand of VFD, PLC through Network.

4. User based Modbus, Profibus, TCP, RS232 protocol.

5. User based Real-Time functional SCADA mobile application.

6. Integration to Mail server, for SCADA based mail / Report generation.

7.Integration of Multiple units / equipment, PLCs under one SCADA.

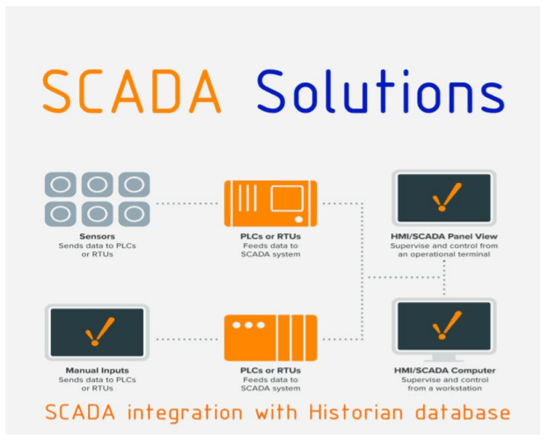

Our SCADA Solution

SCADA is an acronym for “supervisory control and data acquisition.” It is a system that monitors and controls vital infrastructure, such as power, water, gas, and oil distribution systems. SCADA systems are used in many industries, such as manufacturing, mining, healthcare, and transportation. SCADA systems use software-based devices that monitor, gather, and process real-time data. In turn, these systems are controlled by human-machine interface (HMI) software that uses a graphical user interface. SCADA solutions allow businesses to operate their systems more efficiently and safely. They can also monitor performance in real-time so that if there are any issues with the system, they can be fixed quickly. SCADA solutions can also help prevent accidents from happening by detecting potential problems early on.

SCADA solutions are very important because they allow plant operators to monitor and control the operation of their plants from a centralized location. This can help them avoid costly mistakes and disruptions, and it can also improve efficiency by allowing operators to centrally adjust parameters like temperature and pressure. Because SCADA systems are so important, you must choose the right one for your specific needs. If you’re looking for a reliable solution that will meet your requirements for safety and security, then you should consider using a SCADA solution.

Our SCADA solutions are increasingly pushing the boundaries of traditional systems to go beyond simple process monitoring. We provide solutions that integrate all of your manufacturing processes and energy management systems with your SCM and ERP modules, providing you with a uniform interface to your facility.

Electrical drawing development is the process of designing and creating a plan or diagram that shows the layout, configuration, and function of an electrical system. Schematics, wiring diagrams, and other documentation for electrical engineers are frequently illustrated using electrical drawings. One of the top companies offering electrical drawing development services is Precision Scientific Equipment. Our team of professionals uses the most up-to-date technology and years of industry expertise to produce flawless drawings that are correct and error-free. We constantly work to produce the greatest outcomes since we recognize that quality is essential when it comes to electrical drawings.

The Electrical Control System Drawing (ECSD) is a vital document that every electrical contractor, engineer, and technician should have. It is a visual representation of the electrical system and is used to diagnose and repair problems. ECSD from Precision Scientific Equipment is the finest in the business because of our cutting-edge hardware and software. Electrical contractors, engineers, and technicians may utilize our ECSDs with confidence since they are precise, readable, and simple to comprehend.

Electrical loop diagram development is the process of creating an electronic schematic diagram of a power system. It is used to identify and document all the components and connections of the electrical system, as well as to make appropriate design recommendations. Precision Scientific Equipment is the leading supplier of ELDs in the world, and our products are used by some of the biggest names in the industry. With the use of cutting-edge technology, we can produce precise, comprehensive, and simple-to-use ELDs. Additionally, we provide a variety of customization options so that you may obtain the precise ELD you want for your unique requirements.

Electrical Control Panel Building is a new and innovative way of building electrical systems that are both safe and efficient. It’s a system that uses advanced technology to control the flow of electricity straightforwardly. Precision Scientific Equipment offers a wide range of products and services that are ideal for electrical control panel buildings. We work with clients to design, develop, and manufacture the best control panels available today. We offer a variety of panel types, including panels for residential and commercial applications. In addition, we provide a selection of panel patterns and configurations, as well as mounting alternatives.

Instrumentation & Electrical Erection, and Commissioning & Consultancy

As a “one-stop solution supplier” for automated processing facilities and bulk material handling, we are among the top service providers in the Kingdom of Saudi Arabia for Instrumentation & Electrical Erection. We act as a solution provider based on principles and methods that are comprehensive, client-focused, and customer-oriented. We help with setting up, installing, commissioning, and organizing routine maintenance for your equipment.

In addition, we are delighted to create special service agreements according to your requirements. We provide comprehensive project management services that cover design engineering, AutoCAD, CAD Worx 3D, ProE solids drawings, and ASME code welding. Plus, we provide field start-up, commissioning, calibration, training, and quality assurance testing, and operate as a single source for purchase orders.

Analytical instrumentation is used to measure and monitor a variety of parameters in a facility or system. These parameters can include but are not limited to, water quality (H2S, pH, conductivity, density, humidity), air quality (toxic gas, oxygen concentration, turbidity), plant health (conductivity, density, moisture content), and energy production (combustible gas).

Flow meters are instruments that use a variety of methods to measure the flow of liquids, gases, or other fluids. These include coriolis flow meters (which measure the rotation of the fluid), thermal mass flow meters (which use a thermometer to measure temperature), electromagnetic flow meters (which use an electric current or magnetic field to measure movement), turbine flow meters (which use a rotor to gauge speed), and vortex flow meters (which use vortices to measure movement).

Differential pressure flow elements are generally mounted on a sensor arm and used to measure airflow characteristics such as velocity, direction, and turbulence.

There are various types of differential pressure flow elements: eccentrics, conditioning orifice plates, and venturi tubes. Eccentric differential pressure flow elements are used to measure turbulent flows, while conditioning orifice plates are used to measure laminar flows. Venturi tubes are typically used to measure inertial flows (such as gas or liquid streams) or compressible flows (such as air).

In addition, wedge meters are also commonly used to measure static pressures in pipelines. Pitot tubes are typically used to measure speed and head in fluid systems. A V-cone is a type of instrument that measures the effects of lift on fluid motion. Open channels are another type of differential pressure flow element that measures equal-level flows through open channels at various elevation angles.

Flow switches are a type of instrumentation that measures different types of fluid flow. They come in a variety of sizes and shapes and can be mounted on pipes, valves, or other components. There are four main types of flow switches: diaphragm, turbine wheel, orifice plate, and needle valve.

Diaphragm flow switches use a thin membrane to control the size of the open area in the valve. Thrust wheel flow switches work by rotating a wheel with hundreds of blades. This creates an interference pattern that slows down or stops the motion of the fluid passing through it. Orifice plate flow switches use smooth ridges on an exit surface to restrict or allow fluid passage. Needle valve flow switches are similar to orifice plate flow switches, but they use small needles instead of ridges to restrict or allow fluid passage.

Variable-area flowmeters, also known as rotameters, are instruments that measure the rate of flow or discharge of a fluid. They are used in various industries to measure the performance of valves, pumps, and other components. There are three main types of variable area flowmeters: static rotameters, moving rotameters, and dynamic rotameters.

Static rotameters are the simplest type of meter and work by measuring the flow of water through a channel in a fixed position. Moving rotameters are similar to static rotameters, but they can move along the channel to measure fluctuations in the flow. Dynamic rotameters are the most advanced type of meter and can detect both large and small fluctuations in water flow.

Level transmitters are devices that allow for the transmission of energy or information over a certain distance. Radar is the most common type of level transmitter, and it uses radio waves to send signals. Guided-wave radar uses short pulses of energy that are precisely directed so that they can travel as far as necessary without being scattered. Differential pressure level transmitters use a pressure difference to send signals in one direction. Ultrasonic level transmitters send signals over long distances by using sound waves. Displacer-level transmitters use displacement to send signals long distances. Capacitance-level transmitters use capacitive coupling to send signals over long distances. Floating-level transmitters use fluidics to send signals long distances.

Level gauges are instruments used to measure the level of a liquid or a solid within a container or a vessel. There are various types of level gauges available, such as mechanical, electronic, and optical level gauges. A mechanical level gauge is a type of instrument used to measure the level of a liquid or a solid within a container or vessel. It works by using a physical mechanism to indicate the level of the material being measured. Precision Scientific Equipment is a company that provides instrumentation services, including the repair, calibration, and maintenance of level gauges and other measuring instruments.

Pressure transmitters are devices that measure the pressure of a fluid or gas and transmit a signal representing the measured pressure to a remote location. They are commonly used in industrial and process control applications to monitor and control pressure in systems such as pipelines, tanks, and vessels. Absolute pressure transmitters measure the pressure of a fluid or gas relative to a perfect vacuum, which is defined as a pressure of zero. They are often used in applications where it is important to measure the pressure of a fluid or gas with respect to atmospheric pressure. Gauge pressure transmitters measure the pressure of a fluid or gas relative to atmospheric pressure. They are commonly used in applications where it is important to measure the pressure of a fluid or gas with respect to the ambient environment. Differential pressure transmitters measure the difference in pressure between two points in a system. They are often used to measure the flow rate of fluids or gases through pipes or other types of flow meters.

Temperature transmitters and temperature switches are devices that are used to measure and control the temperature in a system or process. Temperature transmitters are devices that measure the temperature of a system or process and transmit a signal representing the measured temperature to a remote location. They are commonly used in industrial and process control applications to monitor and control the temperature in systems such as pipelines, tanks, and vessels.

Temperature switches are devices that are used to detect and respond to changes in temperature in a system. They are commonly used to trigger alarms or shut off valves in response to high or low-temperature conditions. Temperature switches are often used in applications where it is important to maintain a certain range of temperatures, such as in the food and pharmaceutical industries. Both temperature transmitters and temperature switches can be used in a variety of applications, including HVAC systems, refrigeration systems, and industrial process control systems. They are available in a range of types and styles, including digital, analog, and programmable, to suit the needs of different applications.

Gauges are devices that are used to measure and display the value of a particular physical quantity, such as temperature, pressure, or flow.

Temperature gauges are instruments that are used to measure the temperature of a system or process. They may be used to monitor the temperature of a system to ensure that it is operating within a certain range or to control the temperature of a system by activating alarms or shut-off valves when the temperature exceeds a certain threshold. Temperature gauges are available in a range of types, including analog dial gauges, digital display gauges, and infrared thermometers.

Pressure gauges are instruments that are used to measure the pressure of a fluid or gas in a system or process. They may be used to monitor the pressure of a system to ensure that it is operating within a certain range or to control the pressure of a system by activating alarms or shut-off valves when the pressure exceeds a certain threshold. Pressure gauges are available in a range of types, including analog dial gauges, digital display gauges, and electronic pressure transducers.

Flow gauges are instruments that are used to measure the flow rate of a fluid or gas in a system or process. They may be used to monitor the flow rate of a system to ensure that it is operating within a certain range or to control the flow rate of a system by activating alarms or shut-off valves when the flow rate exceeds a certain threshold. Flow gauges are available in a range of types, including analog dial gauges, digital display gauges, and electronic flow meters.

Gauges are commonly used in industrial and process control applications to monitor and control the various physical quantities that are important to the operation of a system or process.

Thermocouple assemblies and resistance temperature detectors (RTDs) are types of temperature sensors that are used to measure the temperature of a system or process. Thermocouple assemblies consist of two wires made from different types of metal that are joined together at one end. When the temperature at the junction of the two wires changes, it causes a voltage to be generated across the wires. This voltage can be measured and used to calculate the temperature of the system or process. Thermocouple assemblies are often used in high-temperature applications, such as in the industrial and automotive industries.

Resistance temperature detectors (RTDs) are sensors that use the resistance of a metal wire or element to measure temperature. The resistance of the wire or element changes as the temperature changes and this change in resistance can be measured and used to calculate the temperature of the system or process. RTDs are often used in applications where a high degree of accuracy and stability is required, such as in the chemical and pharmaceutical industries. Both thermocouple assemblies and RTDs can be mounted in various types of assemblies, such as probes or immersion sensors, to enable them to measure the temperature of a system or process in a variety of applications.

Single-loop controllers are devices that are used to control a single process variable, such as temperature, pressure, or flow rate, in a system or process. They are commonly used in industrial and process control applications to maintain the stability and efficiency of a system by automatically adjusting the output of a control element, such as a valve or a pump, in response to changes in the process variable.

Single-loop controllers are designed to accept a signal from a sensor or transmitter that measures the process variable, compare the measured value to a setpoint or target value, and generate an output signal to a control element based on the difference between the measured value and the setpoint. The output signal is used to adjust the control element to bring the process variable back to the set point.

Single-loop controllers are available in a range of types, including analog, digital, and programmable, to suit the needs of different applications. They can be configured to control a wide range of process variables and can be used in a variety of industries, including manufacturing, chemical processing, and oil and gas.

Why Choose Us for Automation Service in Saudi Arabia?

Some things you may want to consider when evaluating a provider of instrumentation services include:

The range and types of services: We offer the specific services that you need, such as calibration, repair, or installation. We have experience working with the types of instruments and systems you have in place.

Level of expertise and technical knowledge: We have qualified and experienced technicians who are knowledgeable about the latest techniques and technologies in the field.

Track record and customer reviews: We have a good reputation and a history of satisfied customers. All of our customers have to say about our services

Availability and responsiveness: We have the capacity to meet your needs in a timely manner. We can also provide on-site support if needed.

Pricing and value for money: We offer competitive prices for our services. We are transparent about our costs and do offer value for the services we provide.

By considering these and other factors, you can rest assured that Precision Scientific Equipment is best suited to meet your instrumentation needs.